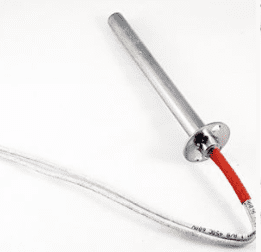

Cartridges are a little-known champion of the heating world but have a significant impact in many areas of our daily lives. From food prep to fuel cells, chemical engineering to extrusion, there is very little which the seemingly humble cartridge heater cannot achieve. This versatility, however, can be a downside. It means it can be tricky deciding which is the best option to choose. This decision depends on a variety of circumstances, such as the application and environment, as well as your budgets. Here are our top tips for picking the best cartridge heater for your needs to help you make a decision.

Where will it be?

The physical environment in which you are planning to place the heater is crucial, as this will determine which materials are used. Incorrect packaging could cause leaks or damage or prevent the element from adhering effectively to the intended surface. It is also important to consider the possible impact of surrounding materials. Aluminum and brass can be particularly tricky. Where possible, it is best to pick a component which comes with an anti-seize mechanism. This will help to improve longevity and mean less maintenance in the future.

How fast should it respond?

Depending on the environment, it may be essential for the heater to respond immediately once activated. Those with higher wattages are best for this, as this ensures a faster response time and a more reliable performance. High wattage heaters are ideal for packaging, plastics, and rubber manufacturing.

What temperatures are required?

Cartridge heaters are, by their nature, exposed regularly to high temperatures. The temperature required will determine the sheathing used on the heater. Choosing the right sheathing material will increase the lifespan of the heater and reduce the need for ongoing maintenance.

How energy efficient does it need to be?

The current buzzword in all areas of manufacturing is, of course, energy efficiency. Modern technology has evolved to make this feature a priority, and it is now possible to pick a cartridge heater which offers more significant energy efficiency, with certain materials selected for their thermal conductivity, increasing efficiency with less power required. This means the device heats up more quickly, saving time, money, and energy.

Down to the wire

The type of lead wire required is also an important consideration, and again, this depends on the temperatures required. If the heater will be used in higher-temperature applications, fiberglass is the best choice for your lead wires. Other materials such as rubber, silicone, or silicone impregnated fiberglass will prove ineffective at extreme temperatures and can be devastating if used in setting such as motor vehicles.

Choosing the right type of cartridge heater can be confusing. It is best to start by thinking about the application. By considering why and what you will be using the heater for, you can evaluate crucial features such as temperature, humidity, physical surroundings, and suitability of certain materials. It is advised to get in touch with an expert, such as those at Rama Corporation, if you are still unsure as getting the proper cartridge heater is a crucial part of your overall project.